-

Terei mofuta fatše mofuta hlama sheeter 400 * 1700mm 500 * 2000mm 610 * 2800mm

Mochine ona o loketse bakeng sa pastry, crisp cake, melaleuca crisp, etc.e ka boela ea sebelisoa ho roala hlama.ka thepa e khethehileng le mokhoa oa ho etsa thepa, lerata le tlaase, le bonolo ho apara, le tšoarella.

-

Mofuta oa rack 32 trays 64 trays hlama proofer douigh fermenting box

The hlama proofer e etsoa ho ea ka molao-motheo le ditlhoko tsa bohobe belisoa le moralo oa lihlahisoa tsa motlakase futhumatsang, e sebelisa mocheso mocheso phala ka potoloho ea mocheso oa mocheso ho futhumatsa terei ea metsi ka lebokoseng, e le hore mongobo o lekanyelitsoeng oa 80 ~ 85%, mocheso oa 35 ℃ ~ 40 ℃. tlhahiso ea bohobe.

-

Li-tray tse 32 tsa ontong ea rotary ea khase ea motlakase ea diesel e futhumatsang e rekisoang ka onto ea rotary e nang le ts'ebetso ea mouoane.

E loketse li-biscuits, shortbread, pizza le khoho e halikiloeng le ho baka matata

The 32 rotary oven e etselitsoe ho fetola indasteri ea ho baka, e fa baapehi tharollo e fapaneng le e sebetsang bakeng sa litlhoko tsohle tsa bona tsa ho baka.

搜索

复制

-

Literei tse 32 tsa rotary gase ea motlakase ea diesel e futhumatsang onto e le 'ngoe ea trolley rotary bakeng sa ho baka

E loketse li-biscuits, shortbread, pizza le khoho e halikiloeng le ho baka matata

The 32 rotary oven e etselitsoe ho fetola indasteri ea ho baka, e fa baapehi tharollo e fapaneng le e sebetsang bakeng sa litlhoko tsohle tsa bona tsa ho baka.

-

Li-trays tse 68 tsa rotary gase ea motlakase ea diesel e futhumatsang onto e le 'ngoe ea trolley rotary e nang le ts'ebetso ea mouoane.

E loketse li-biscuits, shortbread, pizza le khoho e halikiloeng le ho baka matata

Ovine ea 68 rotary e etselitsoe ho fetola indasteri ea ho baka, ho fa baapehi tharollo e fapaneng le e sebetsang bakeng sa litlhoko tsohle tsa bona tsa ho baka.

搜索

复制

-

Li-tray tse 16 tsa rotary gase ea motlakase ea diesel e futhumatsang ka onto ea ho baka e chesang moea o rotary bakeng sa ho baka

E loketse li-biscuits, shortbread, pizza le khoho e halikiloeng le ho baka matata

Ovine ea rotary ea literei tse 16 e na le sistimi ea rack e potolohang e netefatsang kabo ea mocheso, e hlahisang thepa e apeiloeng hantle nako le nako. Ka hare ho sebaka se seholo se ka amohelang li-trays tse 16 ka nako e le 'ngoe, ontong ena e felisa tlhokahalo ea kamehla ea ho beha leihlo le ho potoloha ha literei, e leng se lumellang hore ho be le ts'ebetso e ntle le e bonolo ea ho baka.

-

sprial mixer with lifter, automatic discharge for bread bread hlama mixer planetary hlama mixer

Motsoako oa rona oa hlama oa spiral o na le mochini o matla oa ho phahamisa o felisang mosebetsi o boima oa ho phahamisa, o lumellang basebelisi ho sebetsana le hlama e ngata habonolo le ka polokeho. Ho phahamisa ha bonolo ho phahamisa le ho theola sekotlolo se kopanyang, ho fetisa hlama ka mokhoa o tsitsitseng ho tloha ho mixer ho ea sethaleng se latelang sa mokhoa oa ho baka. Karolo ena e tsoetseng pele ha e boloke nako le mosebetsi feela, empa hape e tiisa sehlahisoa se tsitsitseng, sa boleng bo holimo nako le nako.

-

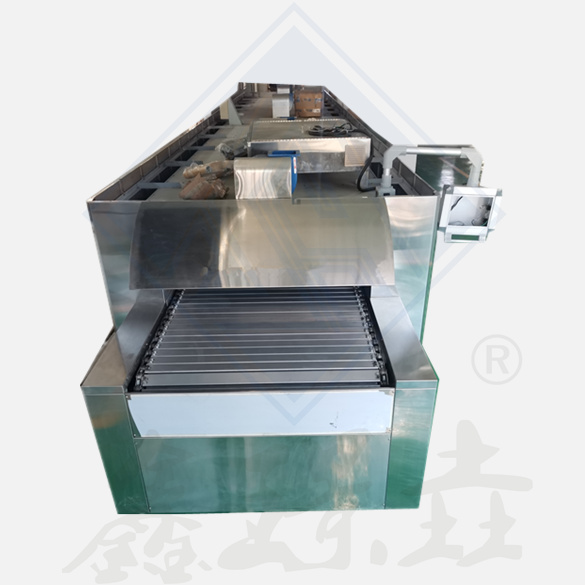

Setofo sa conveyor setofo sa lijo tsa motlakase tsa indasteri ea naan tonnel ontong bakeng sa bohobe ba pita

Ovine ea kotopo ke onto e feto-fetohang haholo ebile e ka etsoa ka mokhoa o ikhethileng e fanang ka melemo e mengata bakeng sa mohala oa hau oa tlhahiso. E 'ngoe ea melemo ea mantlha ea mofuta ona oa onto ke bokhoni ba ho e etsa hore e finyelle litlhoko tse khethehileng tsa tlhahiso. Sena se bolela hore litekanyo, bolelele ba kotopo le lebelo la conveyor li ka fetoloa habonolo nakong ea moralo ho lumellana le litlhoko le mofuta ofe kapa ofe oa ho pheha. Hore na o hloka ho baka litoeba tse nyane tsa likuku tse bonojoana kapa bohobe bo bongata bo thata, lionto tsa rona tsa kotopo li ka hlophisoa ho latela litlhoko tsa hau.

-

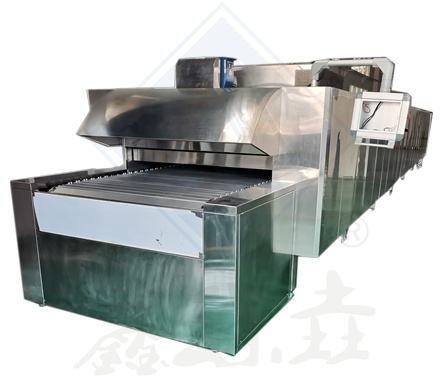

10 metres kotopo ea ontong ea khoebo ea ho baka ontong ea motlakase bakeng sa likuku tsa ho baka

Ovine ea kotopo ke sesebelisoa se feto-fetohang le se ka tšeptjoang se ka sebetsanang le lihlahisoa tse fapaneng ho kenyelletsa bohobe, likuku, pizza le tse ling. Ka moralo oa eona o tsoetseng pele le theknoloji, onto ena e netefatsa liphetho tse tsitsitseng tsa ho baka nako le nako. Ka hare ho sebaka se seholo se lumella tlhahiso ea bokhoni bo phahameng, e leng se etsang hore e be se loketseng bakeng sa khoebo e batloang haholo.

-

600kg / h Full Automatic Hard soft soft Candy Production Line

Ke lipompong tsa mofuta ofe tseo re ka li hlahisang ka mohala o felletseng oa tlhahiso ea lipompong?

Ho lokile, menyetla ha e fele! Ka thekenoloji ea morao-rao le mechine e tsoetseng pele, mohala o feletseng oa tlhahiso ea lipompong o ka hlahisa mefuta e mengata ea lipompong, ho akarelletsa le lipompong tsa mebala e 'meli, lipompong tsa mebala e le' ngoe, lipompong tse ngata le libopeho tse fapaneng.

Mohala oa tlhahiso o na le taolo ea PLC ho sebetsana le ho pheha vacuum ea lipompong, ho tsamaisa le ho beha lits'ebetso. Sena se tiisa tlhahiso e nepahetseng le e sebetsang hantle, e hlahisang lipompong tsa boleng bo holimo nako le nako. Ho feta moo, mohala o khona ho tlatsa litharollo tse lekantsoeng tsa motsoako, pigment le asiti, e lumellang ho theoa lipompong tse ikhethang le tse monate.

E 'ngoe ea likarolo tse hlahelletseng tsa mochini ke sesebelisoa sa eona sa ho beha lithupa, se fanang ka botsitso bo botle le ho ts'epahala. Sena se etsa bonnete ba hore pompong e 'ngoe le e' ngoe e entsoe hantle 'me e loketse ho paka. Ho feta moo, mohala oohle oa tlhahiso o entsoe ho nahanoa ka bohloeki, o nang le sebopeho se kopaneng le ts'ebetso e tšepahalang. Sena ha se netefatse feela boleng le polokeho ea lipompong empa hape se etsa hore ho be bonolo ho hloekisa le ho hlokomela.

Ka boemo bona ba thekenoloji le ho nepahala, mohala oa tlhahiso o ka etsa mefuta e mengata ea lipompong, ho kenyelletsa le lipompong tsa mebala e 'meli, tse nang le mebala e' meli e sa tšoaneng ka sengoathoana se le seng. Lipompong tsa 'mala o le mong li boetse li hlahisoa habonolo, li fana ka phekolo ea khale le e sa feleng. 'Me bakeng sa ba batlang khetho e tsotehang haholoanyane, mohala oa tlhahiso o ka boela oa hlahisa lipompong tse ngata, tse nang le mookoli oa li-hues karolong e' ngoe le e 'ngoe.

Qetellong, mohala o feletseng oa tlhahiso ea lipompong o fana ka bokhoni ba ho hlahisa mefuta e mengata ea lipompong, ho tloha likhethong tsa khale tsa mebala e le 'ngoe ho ea ho tse ling tse ikhethang tse peli le mefuta e mengata le lipompong tse nang le mefuta e mengata. Ka theknoloji ea eona e tsoetseng pele le bokhoni ba tlhahiso e sebetsang, menyetla ea ho bōpa lipompong e batla e se na moeli. Kahoo, ho sa tsotellehe hore na u lakatsa pheko ea setso kapa confection e ncha, kholiseha hore u na le mohala o feletseng oa tlhahiso ea lipompong.

-

450kg/h 3D flat lollipop full automatic line production line

Shanghai Jingyao Industrial Co., Ltd., re utloisisa bohlokoa ba ho sebetsa hantle tlhahisong ea li-confectionary. Ke ka lebaka leo baetsi ba rona ba lipompong tse thata ba ka sebelisang le ho kopanya metsoako e kang tatso, mebala le litharollo tsa asiti ka mokhoa o le mong o hlophisitsoeng. Sena se boloka nako le matla, se eketsa tlhahiso. Ka mechini ea rona, o ka kholiseha hore lipompong tsa hau ha li na sekoli. Conveyor chain, sisteme ea ho pholisa, le lisebelisoa tse hahang habeli li sebelisana ntle le moroallo ho etsa bonnete ba ho theola le ho thella ha lipompong tse fapaneng. Hore na o batla lipompong tse chitja, lipompong tse bōpehileng joaloka pelo, kapa sebopeho sefe kapa sefe sa tloaelo, mochini oa rona o u koahetse. Joaloka moetsi ea ka sehloohong indastering ea mechine ea lijo, Shanghai Jingyao Industrial Co., Ltd. e ithorisa ka ho fana ka mechine ea boleng bo phahameng ho eketsa tlhahiso le katleho mosebetsing oa tlhahiso ea lijo. Ka lilemo tsa boiphihlelo le boiphihlelo, re fetohile lebitso le tšepahalang indastering. Mechini ea rona ea ho etsa lipompong tse thata ke karolo e le 'ngoe feela ea boitlamo ba rona ba ho fa bareki ba rona theknoloji ea maemo a holimo le ts'ebetso e tšepahalang. Khetha mechine ea rona ea ho etsa lipompong tse thata 'me u bone phapang ea tlhahiso ea lipompong. Ikopanye le rona kajeno ho ithuta haholoanyane ka mochini ona o mocha le hore na o ka fetola tšebetso ea hau ea confectionery joang.

-

300kg/h Jelly candy manufecturing mela e 'meli hlobo ea lipompong line ea tlhahiso

Shanghai Jingyao Industrial Co., Ltd. e teng Shanghai, China. E khethehileng ka ho etsa thepa ea ho etsa lipompong. Re na le lefapha la rona la R&D le setsi sa tlhahiso ea litsebi.

Khoebo ea rona ke moetsi ea hloahloa oa lisebelisoa tsa ho etsa lipompong tse nang le nalane ea lilemo tse fetang mashome a mararo e ikhethileng ho hlahiseng metjhini le lisebelisoa bakeng sa mohala o joalo oa (semi) o ikemetseng o thata / o bonolo oa tlhahiso ea lipompong ect.

Re hapile botumo ba rona ka sistimi ea rona e tiileng ea netefatso ea boleng, matla a matla a tekheniki, mekhoa ea ts'ebetso ea mahlale le lits'ebeletso tse ntle haholo tsa kamora ho rekisa.

Lihlahisoa tse ka sehloohong tsa mochini oa lijo: Laola Mochini oa ho Beha Lipompong, Pitsa ea ho pheha Tsoekere, Tunnel Cooling ea Candy joalo-joalo.